Rockfall control – Geogrids – Costa Verde, Lima, Peru.

Cases1. El problema Los acantilados de la Costa Verde, en Lima, presentan problemas de desprendimiento de rocas en la carretera,...

View case Category

Category

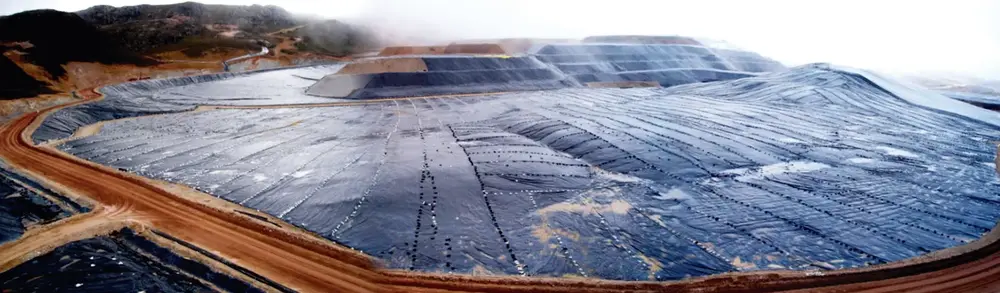

The waterproofing of the Lagunas Norte leach pad has completed Phase 2, a project TDM has been carrying out since Phase 0. The total ore volume at the end of the pad’s useful life will be 115 million cubic meters in a 320,000 m2 area; the material layers will be 10 meters thick, and the final height will be around 150 meters. In Phase 0, the earthmoving contractor was Skanska, and the work consisted of covering a 330,000 m2 area of the leach pad with a smooth HDPE geomembrane. In addition, during this phase, the construction of POP (Pond Overflow Process) and PLS (Primary Leachate System) ponds took place, in whose waterproofing structure GCL (Geosynthetic Clay Liner, a bentonite geocomposite between geotextiles that forms a low permeability layer and replaces the tedious and expensive work of installing a clay layer) was used, two layers of HDPE geomembrane and a geonet between them as a leak detection layer. All of this work was carried out between August 2004 and June 2005. In Phases 1 and 1A, we began working with Empresa de Servicios Múltiples Chan Chan as the earthmoving contractor, installing 360,000 m2 of textured underside geomembrane. The unusual detail was that all of the leachate collection pipes were designed to be confined in trapezoidal channels measuring 1.50 meters in base by 80 centimeters at one meter in height. These pipes are made of ADS N-12 HDPE, corrugated on the outside for greater structural strength and smooth on the inside for better hydraulic conductivity. In Phase 2, recently completed in August 2006, we installed 250,000 m2 of the same type of geomembrane in less than two months, receiving a personal congratulations on-site from Engineer Igor González, Regional President of Barrick Mining. Following the completion of the project, we were asked to carry out additional works, including covering the slopes of Phase 0, whose gradients range between 1:2 and 1:1, with a 1 mm-thick smooth geomembrane, and installing the 70,000 m2 dynamic pad with a 1.5 mm geomembrane. Our continued operation at Lagunas Norte is undoubtedly due to our excellent performance, based on yield, progress, and quality, with zero accidents despite the inclement weather at this altitude (above 4,000 meters above sea level) and its manifestations of rain and wind, which can endanger the safety of field personnel. The success was confirmed by Vector Engineering, the company overseeing the construction work and also providing the design and engineering for Phase 2.

1. El problema Los acantilados de la Costa Verde, en Lima, presentan problemas de desprendimiento de rocas en la carretera,...

View case

1. The Problem In recent years, the Chosica district in Lima has been affected by mudslides that occur in its...

View case